Food Safety and Quality

Above and Beyond

Food safety is of the utmost importance at Ippolito International, LP: from executive management to our harvesters, our employees take an active role in our food safety program. We believe that our food safety strategy sets us apart in two ways: our harvest management and our company culture.

Managed Harvest Operations

Our own farming and harvesting entities, Queen Victoria Farms and Coast King Packing, LLC closely manage Ippolito International’s farming operations. Our core group of growers is committed to Ippolito International’s standards of producing fresh, high-quality vegetables consistently and year-round.

Because of our closely managed harvesting process, we maintain the strict care and handling procedures that are necessary to provide the highest quality fresh vegetables.

A Culture of Empowered Employees

Ippolito International’s approach to food safety is to educate and empower our employees so they have an awareness and interest in maintaining the program’s integrity. Our focus on continuous training to stay up to date with regulations and customer expectations helps foster a strong food safety culture. We go above and beyond what the state and federal government require by conducting impromptu inspections and rigorous training for all our field foremen and supervisors. By spontaneously and regularly placing our food safety personnel in the field and our processing facilities we ensure that our products are fresh and safely handled. This training and impromptu inspections are executed on an ongoing basis.

standards

Ippolito International follows the highest regulations or standards set by customer requirements and the California and Arizona Leafy Greens Marketing Agreement (LGMA), the FDA’s Food Safety Modernization Act (FSMA), the Global Food Safety Initiative (GFSI), and Good Agricultural Practices (GAP).

verification

Our procedures are verified at three levels: internal, state, and third-party audits. The California Department of Food & Agriculture (CDFA) in California and the Arizona Department of Agriculture (AZDA) in Arizona, as well as Primus Auditing Operations and NSF Davis Fresh, conduct these third-party audits.

water

Water sources are identified and monitored before harvest to validate compliance with established standards. Water used during harvest is also tested and verified for compliance.

soil

Soil inputs including fertilizers and additives must be identified and recorded. Soil fertility tests are conducted to ensure the soil is safe and ready for growing.

EnvironMENTal factors

Pre-season risk assessment is conducted to identify potential food safety risks. Mitigation measures must be in place and documented for any food safety risks. Pre-harvest pathogen testing must be completed in all fields before they are harvested. A pre-harvest risk assessment must be performed for each harvested lot within 7 days.

work practices

Field and processing facility employees receive comprehensive training upon hire and throughout their employment tenure. This training covers principles of food hygiene and safety, emphasizing the importance of personal health and hygiene practices in maintaining food safety standards.

field sanitation

Harvest equipment, packing materials, and buildings undergo thorough sanitation procedures to maintain cleanliness and prevent contamination. Daily assessments are conducted during the harvest process to ensure adherence to sanitation protocols and uphold food safety standards.

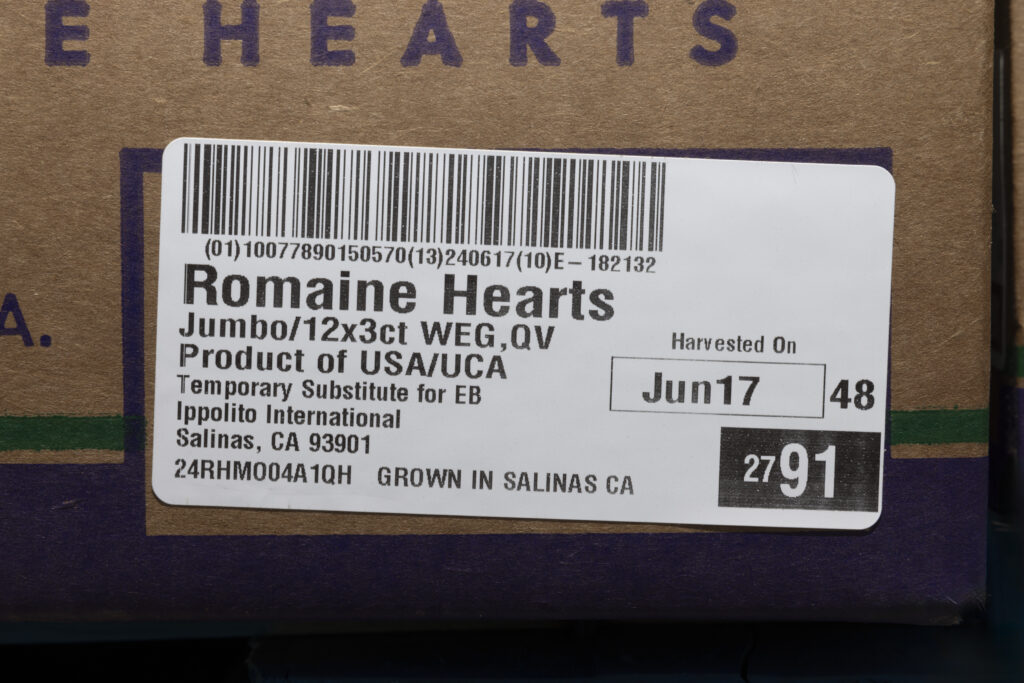

traceability

Ippolito International uses a GTIN program and GS128-compliant PTI stickers to track products from the field to the trucks on which they are shipped. The company is compliant with FSMA Traceability Rule 204, utilizing the GTIN program, GS128-compliant PTI stickers, and advanced shipping notices (ASNs).

CA LGMA Test and Learn Program

Ippolito International, LP is involved in the California LGMA’s Romaine Test and Learn program. Romaine growers throughout the industry are participating in the Romaine Test & Learn two-year food safety study. The study will collect LGMA (Leafy Greens Marketing Agreement) members’ pathogen testing data for romaine lettuce, at both the pre- and post-harvest stages. The goal is to aggregate all the data to understand more about romaine pathogens, and possibly, to inform future food safety practices.

For more information on our Food Safety program, please contact Herman Cossio at herman.cossio@qvproduce.com.